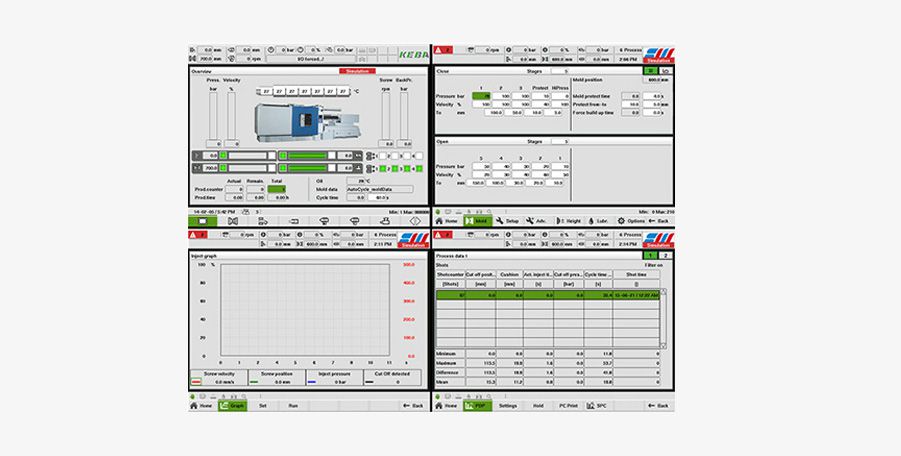

The i-1000 has a real-time function that enables a continuously controlled quality of the production.

i-1000 CONTROL AVAILABLE FOR: ALL MODELS

The hardware of the i-2000 series consists of a high performance single-board computer with scalable performance level. I/O modules or electric drives are connected via the integrated high-speed real-time EtherCAT bus.

i-2000 CONTROL AVAILABLE FOR: CX & MBE SERIES

A part of the powerful software framework is the extensive range of technology functions for controlling the molding process and for implementing molding functions. A wide variety of technology modules like servo valves, or the mold position control is available.

Programming takes place in a uniform, modularly structured, development environment. The operating concept and the scope of the services can adapt to the performance and the target market of the machine in question. Operators, therefore, can have an optimal control system for the IMM regardless of whether the machine is hydraulic, hybrid or electric.

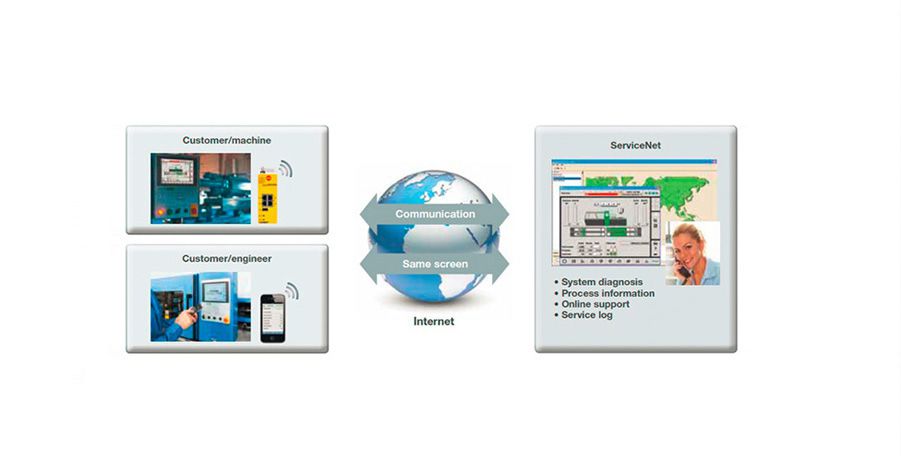

ServiceNet is a user-friendly plug & play solution for comprehensive remote support, and for efficient remote monitoring of the injection molding machines. Fast, worldwide access to process data for service & support as well as a simple remote diagnosis are just as easy and uncomplicated as the convenient support of the operator for different applications and process queries.